We will serialize the sheet metal model production process (Skytree 1/1000 LED) and the model assembly process.

© M.SA

I uploaded a video of the completed Illumination α 1/1000 LED to YouTube.

①

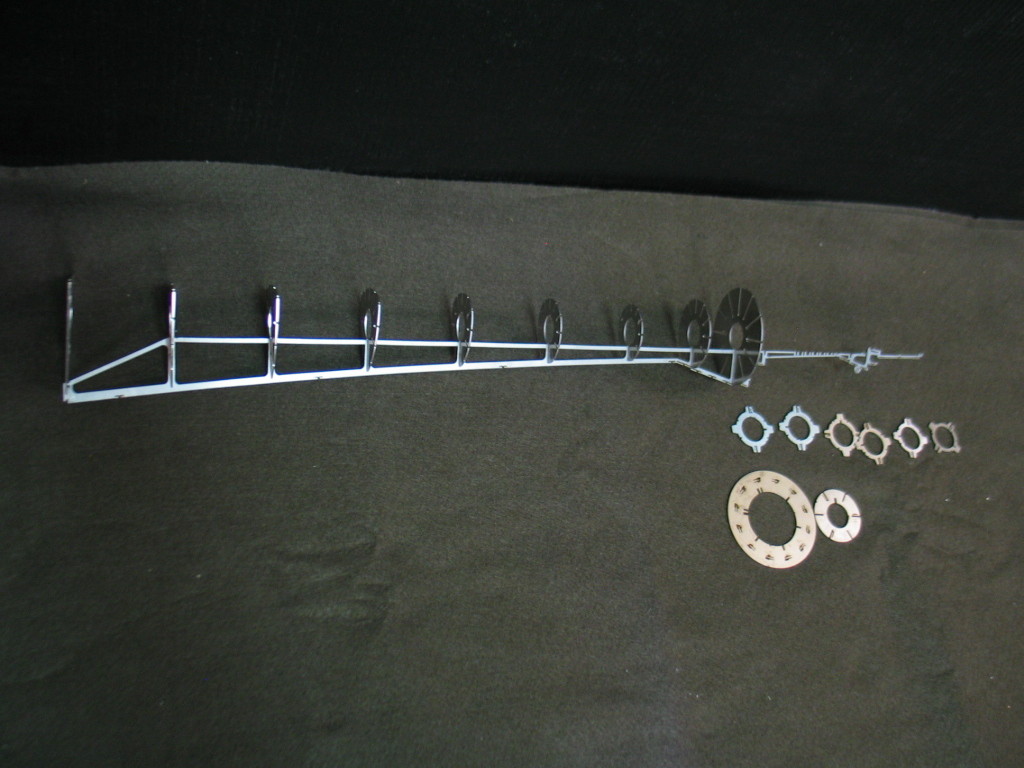

These are the assembly parts (laser cut blanks). The three net parts in the next photo are all included.

There are 46 parts, excluding the base.

②

This is the part that will be wrapped around the side of the Skytree. It is still in its laser cut state.

③

All horizontal components have been inserted into the S1 component.

There are no screws or glues used.

All assemblies are reversible.

④

Close-up of insertion state.

⑤

Close-up of insertion state.

Upper Second Observation Deck,

Below that, the antenna section,

Below that is the first observation deck.

⑥

Inserted into S1. The top part is not inserted yet.

⑦

⑧

First Observation Deck

⑨

⑩

100m above ground.

⑪

An acrylic pipe that acts as the core pillar is inserted in the center.

⑫

First observation deck and second weather deck.

⑬

Assembly of the main mechanism is complete prior to wiring.